Introduction

For overseas buyers sourcing carved wooden boxes wholesale, the challenge is rarely design — it is manufacturing stability at scale.

Carving affects material choice, MOQ, unit cost, yield rate, and delivery risk. Without understanding how carving interacts with wood structure and batch production, buyers often face inconsistency between samples and mass orders.

This guide is written from a China OEM/ODM factory perspective, focusing on real production constraints rather than decorative marketing claims.

What “Carved Wooden Boxes Wholesale” Really Means for Bulk Buyers

In B2B sourcing, carved wooden boxes are not a simple upgrade from flat wooden boxes.

They represent a different production model with higher technical sensitivity.

From a factory standpoint, carved wooden boxes wholesale matters because:

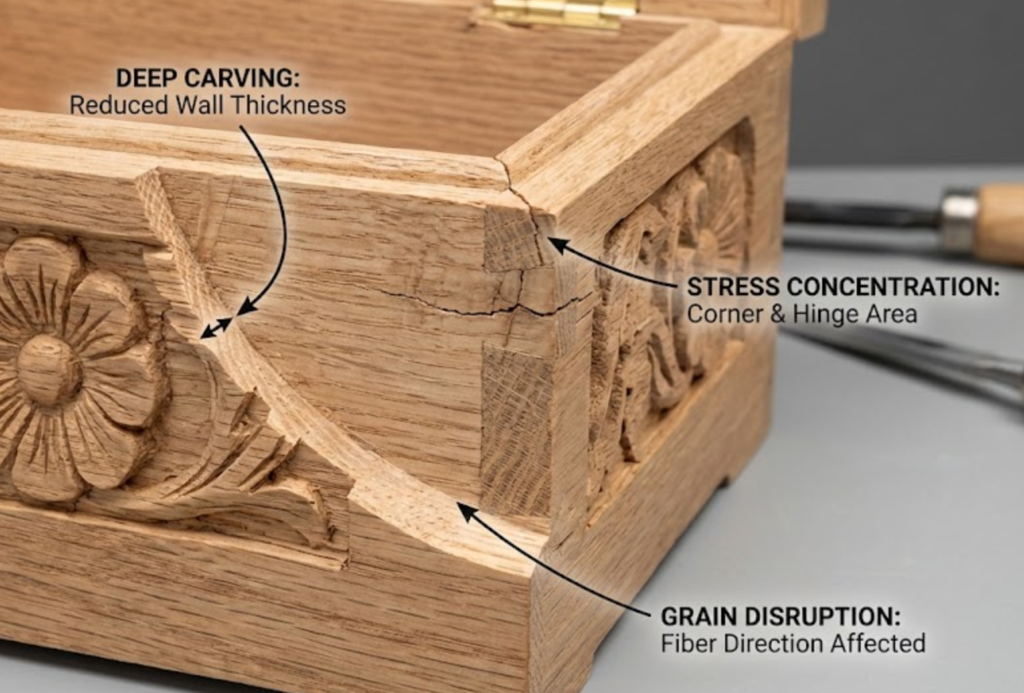

- carving changes wood thickness and stress distribution

- tooling and setup costs increase MOQ thresholds

- design quality determines whether mass production is repeatable

Buyers who treat carving as a surface decoration often underestimate these factors.

Common Buyer Misunderstandings (Factory Reality)

1. “Carving is just an extra process”

In practice, carving directly affects:

- crack risk during drying and shipping

- hinge and corner strength

- acceptable wall thickness

Deep carving without structural adjustment is a common cause of bulk defects.

2. “All woods carve the same”

Different woods react very differently to carving pressure and tool paths.

Material choice defines both visual result and rejection rate.

3. “If the sample looks good, mass production is safe”

Samples often involve manual correction.

Wholesale production requires carving designs that can be repeated by machine with stable tolerances.

Material Differences That Affect Carving Results

From OEM experience, carving performance by material typically looks like this:

- Pine / Paulownia

- Lower cost, easier cutting

- Limited carving depth

- Best for decorative or gift-oriented SKUs

- Acacia / Rubber Wood

- Balanced hardness and grain stability

- Suitable for medium-depth carving

- Common choice for retail and wholesale programs

- Walnut / Hardwoods

- Sharp carving definition

- Higher tooling wear and cost

- Usually requires higher MOQ

For general wood classification and properties, buyers can reference

Wikipedia (hardwood vs softwood overview).

👉 Internal link suggestion:

Link this section to your Material Guide page

Carving Method vs Cost Trade-Off

In wholesale orders, carving method determines cost predictability:

- CNC carving

- High consistency

- Higher initial setup cost

- Best for repeat SKUs and long-term programs

- Hand-assisted carving

- Flexible for small batches

- Higher labor dependency

- Risky for large-volume consistency

For most B2B buyers, CNC-based carving offers the best cost vs effect balance over time.

MOQ & Customization Limits (Factory View)

Carved wooden boxes wholesale almost always requires higher MOQ than plain boxes, because:

- tooling and programming costs are fixed

- yield loss must be absorbed

- setup time does not scale down linearly

Typical OEM logic:

- simpler surface carving = lower MOQ

- deeper or edge carving = higher MOQ

- each new pattern = separate SKU

Factories often recommend standardizing box size first, then customizing carving patterns.

Bulk Production Checklist (What Experienced Buyers Verify)

Before confirming mass production, professional buyers usually check:

- ✔ moisture content suitable for carved structures

- ✔ minimum wall thickness after carving

- ✔ carving depth tolerance across batches

- ✔ edge sharpness and burr control

- ✔ protective packaging for carved surfaces

For compliance-sensitive markets, requirements often include:

- FSC-certified wood (Forest Stewardship Council)

- Formaldehyde emission standards (EPA / CARB where applicable)

How Chic Homeware Handles Carved Wooden Boxes Wholesale

At Chic Homeware, carved wooden boxes are treated as engineered products, not craft items.

Our OEM approach focuses on:

- design-for-production review before sampling

- matching carving depth to wood behavior

- early MOQ and cost breakpoint clarification

- avoiding carving designs that rely on manual correction

We prioritize repeatability and batch stability, which is what long-term wholesale programs require.

👉 Internal link suggestion:

See our Custom Wooden Boxes product category page.

Final Thoughts for B2B Buyers

Sourcing carved wooden boxes wholesale is less about artistic complexity and more about controlled manufacturing.

The right supplier is not the one who promises the deepest carving —

but the one who can deliver consistent carving, stable cost, and predictable lead time at scale.